进口卫生级视镜原理特点

进口卫生级视镜可用于温度高,腐蚀性强、易中毒、危险性较大,易结晶的化工塔器中,以保证其安全生产。

1、清洁处理。在使用前可以用适量酒精棉在其表面轻微擦拭,注意:不要用含有酸性 的液体进行清洁,以免腐蚀玻璃外表面。

2、要正确选择垫片。环境工作温度在280度以内的场合,用石棉垫或四氟垫即可,当环境工作温度超出500℃时,建议选择石墨垫片。注意:玻璃越厚,所以选择的垫片厚度也要跟着相应增加。

3、用力均匀。安装时不可用力过猛、过大,建议均匀用力按对角线方式锁紧螺丝。

4定期检查。视镜玻璃在安装完毕后,还必须做好定期检查工作,特别是在含有酸、碱的液体环境中,更是要做好定期检查玻璃表面受腐蚀程度,以确保一线操作人员的安全。

The in-line sight glasses offered by Thomas are suitable for a wide range of ASME BPE applications in high purity tubing systems typically found in the pharmaceutical or bio-pharma-ceutical industry.

The double window design ensures optimum viewing area and eliminates the need for a back light. The bore of the glass and end fittings match that of the corresponding tubing size, preventing the possibility of fluid retention, even when units are installed horizontally.

The SG Series sight glasses combine 316L stainless steel end connections with a toughened borosilicate viewing glass making them suitable for both clean-in-place (CIP) and steril-ization-in-place (SIP) operations. Standard units are available in 1/2" to 4" sizes with Tri-clamp? compatible connections. Alternative sizes and connection types can also be supplied.

Where there is a risk of accidental damage to the viewing glass, a Polycarbonate shield or perforated viewing tube can be supplied.

Features

Full bore flow path

Large viewing area

Compact design

Metal stop provides ideal o-ring compression and prevents pipe torque from affecting glass

Suitable for CIP and SIP

SF1,20 Ra pin mechanical polish, (0,5 pm Ra) standard

Standards

Where applicable, all sight glass models comply with ASME BPE criteria

All sight glass models are CE compliant under the SEP category of the PED directive

All seal materials are FDA and USP Class VI compliant

Cleaning & Packaging

All sight glasses are cleaned after manufacture, capped, sealed in a polythene bag and individually boxed

Specifications

Sizes: 1/2", 3/4", 1", 1-1,2", 2", 2-1/2", 3", 4"????????

End Connections

Tri-clamp? compatible

Materials of Construction

Body - 316L Stainless Steel

End fitting - 316L Stainless Steel

Glass - Borosilicate

Seals - EPDM, Viton, Silicone FEP-Silicone, or- Perlast (FFKM) (all FDA and USP VI compliant)

Surface Finish

Internal - SF1; 20 Ra pin (0,5 pm) mechanical finish, Electropolish optional

External - 32 Ra pin (0,8 pm) mechanical finish

Operating Conditions

Maximum operating pressure - 145 psig (10 barg)

Maximum allowable temperature with EPDM seals- 1750F(1350C)

Maximum allowable temperature with Silicone, Viton or FEP Silicone seals - 392 F (200 C). seals -392〇F (200〇C)

Maximum allowable temperature with Perlast seals: 401〇F (205〇C), including continuous steam service up to 145 psig (10 bar)

Options

DIN, ISO & SMS sizes available upon request

Electropolished finishes

Perforated viewing tube

Alternative lengths / weld end connections

Certifications

Thomas Unicert

—Traceable Material Heat Number for body and ferrels

—Certificate of Compliance to FDA and USP Class VI

Certificate of Surface Finish

— Final Test Reports and Certificate of Origin available upon request at time of order

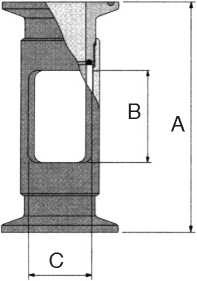

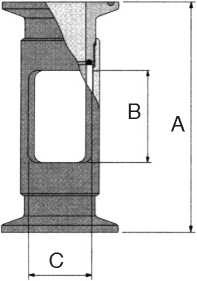

Valve Size | A | B | Viewing Area ℃ |

1/2", 3/4" | 3.54 (90mm) | 1.57 (40mm) | 120° |

1" - 4" | 3.94 (100 mm) | 1.57 (40mm) | 120° |

进口卫生级视镜品牌

德国托马斯阀门集团于1933年创建于德国鲁尔工业区,也是世界最重要的工业区。位于德国西部、莱茵河下游支流鲁尔河与利珀河之间的地区。德国托马斯阀门集团是以生产高品质、先进的阀门、测量及控制系统而享誉全球的跨国性生产企业。采用世界先进的设备及生产工艺,所有产品都在严格的质量体系监控下完成作业。并在各大洲几十个国家拥有子公司及分支机构。