进口卫生级疏水阀原理特点

进口卫生级疏水阀主要用于蒸汽系统中的凝结水、空气和二氧化碳气体尽快排出,同时最大限度地自动防止蒸汽的泄漏。

该阀安装在蒸汽加热设备与凝结水回水集管之间。开启时,桶在底部,阀门全开。凝结水进入疏水阀后,流到桶底,充满阀体,全部浸没桶体,然后,凝结水通过全开阀门排至回水集管。蒸汽也从桶体底部进入疏水阀,占据桶体内的顶部,产生浮力。桶体慢慢升起,逐渐向阀座方向移动杠杆,直到完全关闭阀门。空气和二氧化碳气体通过桶体的排气小孔,聚集在疏水阀的顶部。从排气孔排出的蒸汽,都会因疏水阀的散热而凝结。当进来的凝结水开始充满桶体时桶体开始对杠杆产生一个拉力。随着凝结水位不断升高,产生的力不断增加,直到能够克服压差,打开阀门。疏水阀阀门开始打开,作用在阀瓣上的压差就会减小。桶体将迅速下降,使阀门全开。积聚在疏水阀顶部的不凝性气体先排出,然后凝结水排出。水流从桶体流出时带动污物一起流出疏水阀。凝结水排放的同时,蒸汽重新开始进入疏水阀,新的一个周期又开始了。

The CST Series is a 316L polished, stainless steel thermodynamic disc trap, that is compact with a lightweight design and Tri-Clamp end connections.

Though non-sanitary in the traditional sense, the exterior is polished to 20 Ra and can be used in clean room environments on plant steam, or non-validated clean steam applications. The thermodynamic action meets the requirements of quick response applications in the steam system. Condensate entry below the disc, concentric to the disc/seat ensures a clean parallel lift of the disc with referenceto the seat, eliminating localized wear and tear.

The CSDT is ideal for fluctuating steam loads and pressures. It is virtually maintenance free with a one year replacement warranty.

Features

1、316L body construction

2、20 Ra μin (0,5 Ra μm) external mechanical finish (except at body cap junction)

3、Operates in any position

Specifications

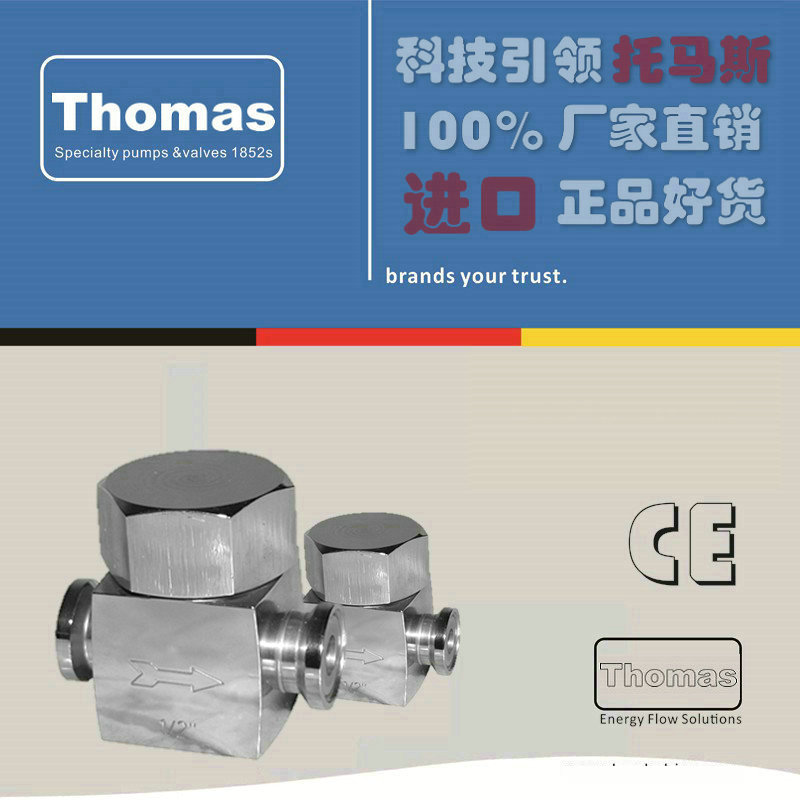

Sizes: 1/2" (DN15) & 3/4" (DN20)

Ends: Tri-Clamp

Materials

Body: Casting, AISI 316L

Disc: AISI 316L

Internal Finish: As cast and machined

External Finish: 20 Ra μin (0,5 Ra μm)

Mechanical finish (except at body/cap junction)

Pressure Maximum Allowable: 227 psig (15,6 barg)

Temperature Maximum Allowable: 842°F (450°C)

Maximum operating back pressure at the outlet should not exceed 80% of the inlet.

Minimum differential pressure for satisfactory operation 3.6 psig.

![进口进口阀门|进口水泵|进口电磁阀|进口气动球阀|进口气动阀门|进口气动蝶阀|进口高压电磁阀|进口气动隔膜泵|进口气动调节阀|进口阀门品牌 进口进口阀门|进口水泵|进口电磁阀|进口气动球阀|进口气动阀门|进口气动蝶阀|进口高压电磁阀|进口气动隔膜泵|进口气动调节阀|进口阀门品牌]()

进口卫生级疏水阀品牌

德国托马斯阀门集团于1933年创建于德国鲁尔工业区,也是世界最重要的工业区。位于德国西部、莱茵河下游支流鲁尔河与利珀河之间的地区。德国托马斯阀门集团是以生产高品质、先进的阀门、测量及控制系统而享誉全球的跨国性生产企业。采用世界先进的设备及生产工艺,所有产品都在严格的质量体系监控下完成作业。并在各大洲几十个国家拥有子公司及分支机构。