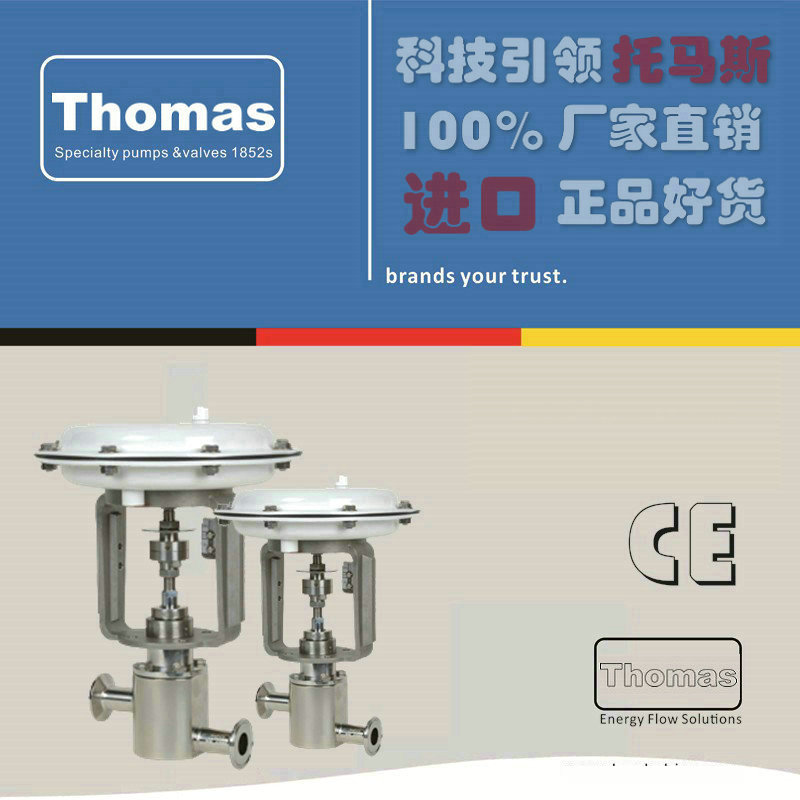

进口卫生级调节阀原理特点

进口卫生级调节阀适用于各种压力、温度、流量等物理量调节,如食品、制药、化妆品、洁净蒸汽、酒类、饮料、生化工业过程控制场合。具有结构紧凑、装拆方便、调节精度高等优点,尤其是在压降损失小、流量大、可调范围广、流量精度高,完全符合IEC534-1-1978标准。阀门泄漏量符合ANSIB16.104标准,调节阀配用不同的多弹簧执行机构,输出力大。

The Mark 978INLINE Series Sanitary Control Valve (with Jorlon diaphragm) is designed to meet the rigid specifications for sterile process and clean utility control valves. This valve series is suitable for a wide variety of applications in the bio-pharmaceutical, parenteral, cosmetic, dairy and food and beverage industries.

The Mark 978 meets ANSI BPE 2009 guidelines, and is ideally suited for a wide range of flowing media in both the clean utility and process areas of sanitary and aseptic systems.

High rangeability, true characterized trim, high capacities, superior temperature and pressure ratings, facilitated by a superior diaphragm, make the MK978 the sanitary control valve for sterile process, buffer, WFI and acid metering, and clean gas and steam services.

The Mark 978 Series comes standard with the Jorlon diaphragm. If you are looking to extend the life of your regulators and reduce the overall cost of ownership, then look no further than Steriflow Valve’s Jorlon diaphragm. Jorlon is a structurally modified PTFE with FDA and USP Class VI approval.

Jorlon is a proprietary modified PTFE material that positively impacts regulator reliability, performance and service life. Since its inception, several thousand Steriflow valves with Jorlon diaphragms have been supplied to customers into systems which have been validated by the FDA. Jorlon has been specified in biopharm applications including (but not limited to) WFI, clean steam (up to 100 psig), buffers, acids, cryogenic liquids, clean utility gas, biological intermediates, and final process fluids. Jorlon is warranted for a lifetime of use in our Mark 95, Mark 96, Mark 96AA and Mark 978 Series.

Whether the need is to control pressure, temperature, flow, pH or another variable, the MK978 is the right valve for your process.

Applications: a wide variety of applications exist for the MK978 in the pharmaceutical, biotech, healthcare and food & beverage and other industries including: fermenter, bioreactor, lyophilization, chromatography, SIP/CIP systems, parenteral filling, bio-process, caustic, acids, buffer, clean steam and WFI.

Sizes:1″ (DN25) through 2″ (DN50)

Body/Bonnet Connection:bolted flange

Body/Bonnet Seal:valve diaphragm serves as bonnet seal

Body/Stem/Bonnet Material:ASTM A479 316L SST barstock

Diaphragm:Jorlon (FDA/USP Class VI to +340°F/171°C)

Stem Bushing:FDA PEEK (no process contact)

Soft Seat Option (Cv>3.5 only)

– PTFE FDA/USP Class VI to +252°F (122°C) continuous or 275°F (135°C) in intermittent (< 15 minutes over one hour)

– PEEK FDA/USP Class VI to +350°F (177°C)

Shutoff:

– Standard: ANSI Class III with metal seat

– Optional: ANSI Class VI with soft seat (Cv>3.5 only)

Ranges:3-15, 6-30, 3-9*, or 9-15* psi (0,2 – 1,0; 0,4 – 2,0; 0,2 – 0,6* or 0,6 – 1,0* bar)

* positioner required

Maximum Pressure @ 100°F (38°C):Jorlon: 150 psi (10,3 bar)

Maximum Pressure/Temperature Rating:Jorlon: 100 si @ 340°F (6,9 bar @ +171°C)

Flow Characteristics:linear, equal percentage, or quick opening (consult factory for quick opening’s Cvs)

进口卫生级调节阀品牌

德国托马斯阀门集团于1933年创建于德国鲁尔工业区,也是世界最重要的工业区。位于德国西部、莱茵河下游支流鲁尔河与利珀河之间的地区。德国托马斯阀门集团是以生产高品质、先进的阀门、测量及控制系统而享誉全球的跨国性生产企业。采用世界先进的设备及生产工艺,所有产品都在严格的质量体系监控下完成作业。并在各大洲几十个国家拥有子公司及分支机构。